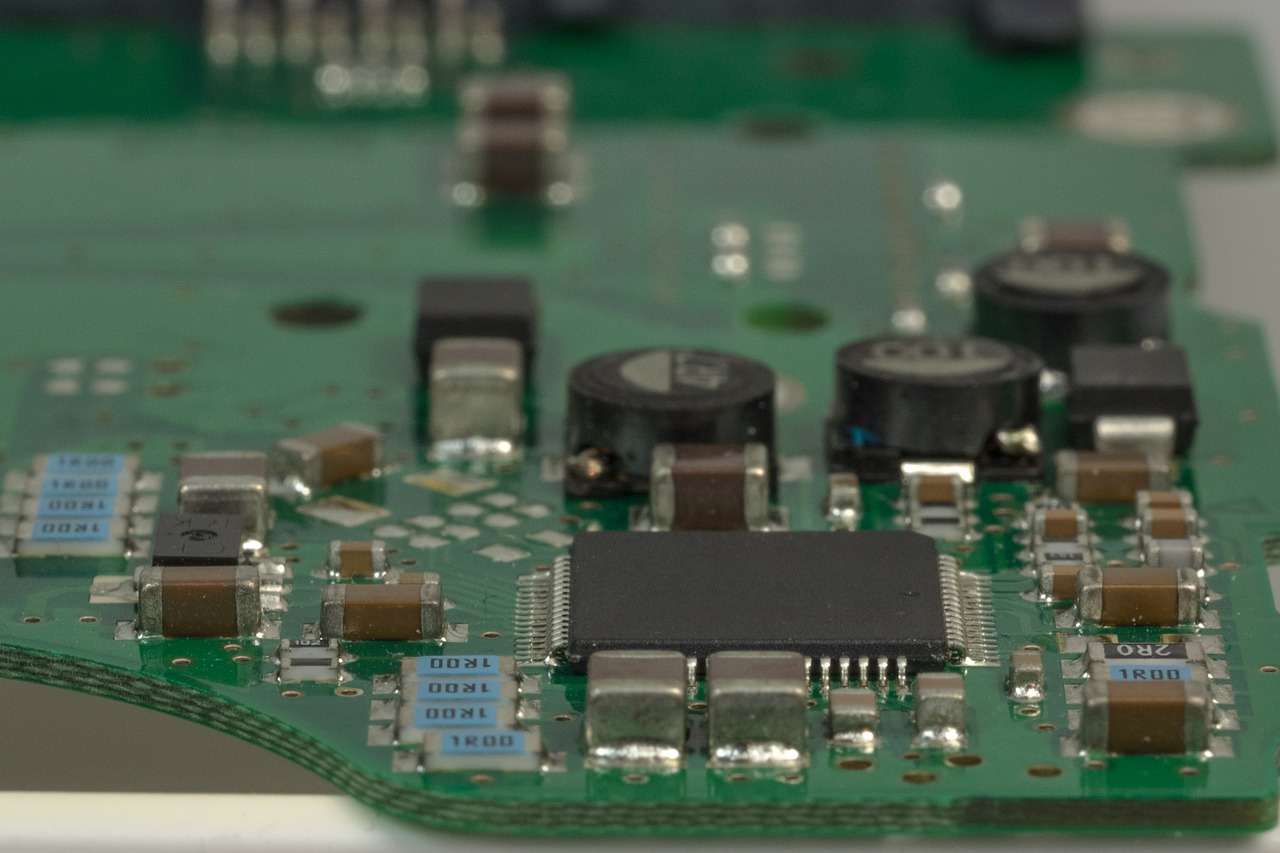

SMT Assembly

In House State Of The Art SMT Assembly | San Jose, CA | 36,000 square feet

Representing the best talent in the industry, Acronics’ experienced engineering team provides quick turn PCBAs and accelerates time-to-market. From conceptual design, new product introduction, prototyping, material selection and purchasing, test development, and design improvement, Acronics offers customers a complete set of manufacturing services.

Quick Turn Around

Assembly in 5 days or less

Quality

ISO 9001:2015 | ISO 13485:2016

Engineering Support

In-house engineering support

Decrease the communication time between teams to increase production speed.Specialized in low volume production

Whether it's 5 or 5,000, emphasis is always on quality

Capabilities

- New 2024 Yamaha SMT Line

- Specialized in high end complex board prototyping

- Lead-free components and processes (RoHS)

- Single and double-sided SMT assembly

- 50+ layer count PCB’s

- Capable to handle small 008004 packages

- Place 5,000 pin BGA’s

- 32″x21″ board sizes

- CCGAs I/O 625-1657

- CBGAs I/O 256-937

- Conformal coating

- Class 1, 2 and 3 capabilities

- Backdrilling and blind via formation

- Embedded passives

- ESD Controlled Environment

Flexible Manufacturing

Using its large manufacturing facility and state-of-the-art SMT machines, Acronics provides flexible manufacturing options that adapt to cost targets, delivery requirements and fluctuating demands in volume. Acronics manufacturing facilities are closely linked with engineering resources, providing a fast ramp from prototype to volume production. Some manufacturing services include:

- Automated final assembly

- BGA assembly, rework and reballing

- Pin through hole (PTH) assembly

- Optical modules, fiber management and splicing

- Exotic fiber splice combinations

- Large board sizes

- Board thicknesses from 0.025″ to 0.150″

- 0.5-inch backplanes with active devices

- 12-mil pitch connectors/QFPs

- Press-fit connectors